To receive accurate and repeatable results it is important to check the accuracy of your test chart illumination. Such an illumination needs to fulfill 3 main criteria:

1. Uniformity

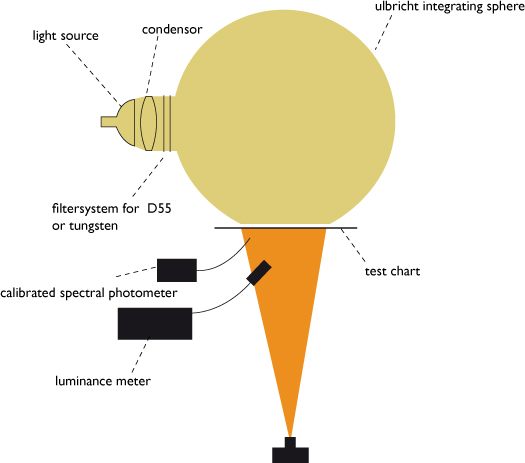

To measure aspects like shading or a lens MTF it is extremely important to have a uniform illumination. For reflective test charts in our A1066 size (app. 83.5 cm in height) the uniformity is usually not higher than 80% – 85%. If a value of 90% can be achieved then the uniformity is as good as it can be. However this is not good enough for a camera shading calibration. To reach higher uniformity levels the integrating sphere, in combination with a transmissive target, is the solution but it is limited in size

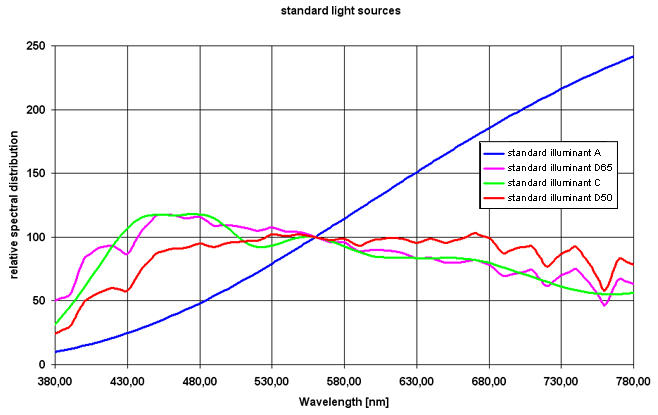

2. Spectral distribution

Especially for color and white balance calibration and tests the spectral distribution of the light source plays an important part in the process. Peaky spectral distributions like those of a fluorescent tube can produce strange results in color reproduction tests. The closer the spectral distributions are to a standard light source like a D50 or D65 or a 3200 K tungsten source, the more accurate the test results will be based on provided reference values. Using distributions close to standard sources also increases the comparability between different test labs.

3. Illumination geometry

For transmissive charts the ideal illumination is a uniform diffuse one. Therefore the integrating sphere is the solution most users choose. For an integrating sphere a light source shines into a sphere that is coated with a matt white paint (barium sulfate) and the chart is aligned perpendicular to the incident light. In this way the light needs to be reflected several times before it falls on the chart itself and the matt surface of the sphere causes a diffuse reflection leading to a diffuse illumination of the chart from various directions.

Reflective charts are usually illuminated using two light sources in a 45° angle that can be arranged either left and right of the camera or above and below the camera. The two sided 45° angle is the preferred one because it is the best compromise between uniformity and the prevention of specular reflections. To avoid specular reflections most reflective targets are made of material with a matt surface. For some targets like a TE42 or TE256 or the UTT at least some parts are made of glossy material to increase the contrast of the target or to allow a wider color gamut. With these targets it is important to check the images for potential specular reflections that may affect the measurement results.

To minimize specular reflections it is best to have a diffuser in front of the light sources. By increasing the distance to the target the illumination becomes more uniform and the probability of specular reflections decreases. But the amount of light reaching the target also decreases with the square of the distance and it requires space. An alternative for avoiding specular highlights is to move the light sources closer to the target thus increasing the angle to the camera. The downside of this is an increase in nonuniformity.

dw