camSPECS V2 measures the spectral sensitivity more effectively by mounting all of the interference filters onto one “test chart.” The newest version uses new high-quality interference filters.

The light source is designed to ensure equal power output for the interference filters and to not exceed the dynamic range of the camera. Neutral density filters in the front plate are used to compensate for possible non-uniformities of illumination.

The camSPECS hardware consists of a metal housing with a stabilized power supply for the halogen light source. The 39 interference filters, mounted on the front plate, provide monochromatic light from 380 nm to 760 nm.

camSPECS XL

The XL version uses the same new high-quality interference filters that were introduced in V2, but now the filters have twice the diameter. This larger version is more suitable for measuring cameras with wide-angle lenses such as those in automotive camera systems.

Hardware

- Illumination box with the filter panel

- Calibration device

camSPECS Software

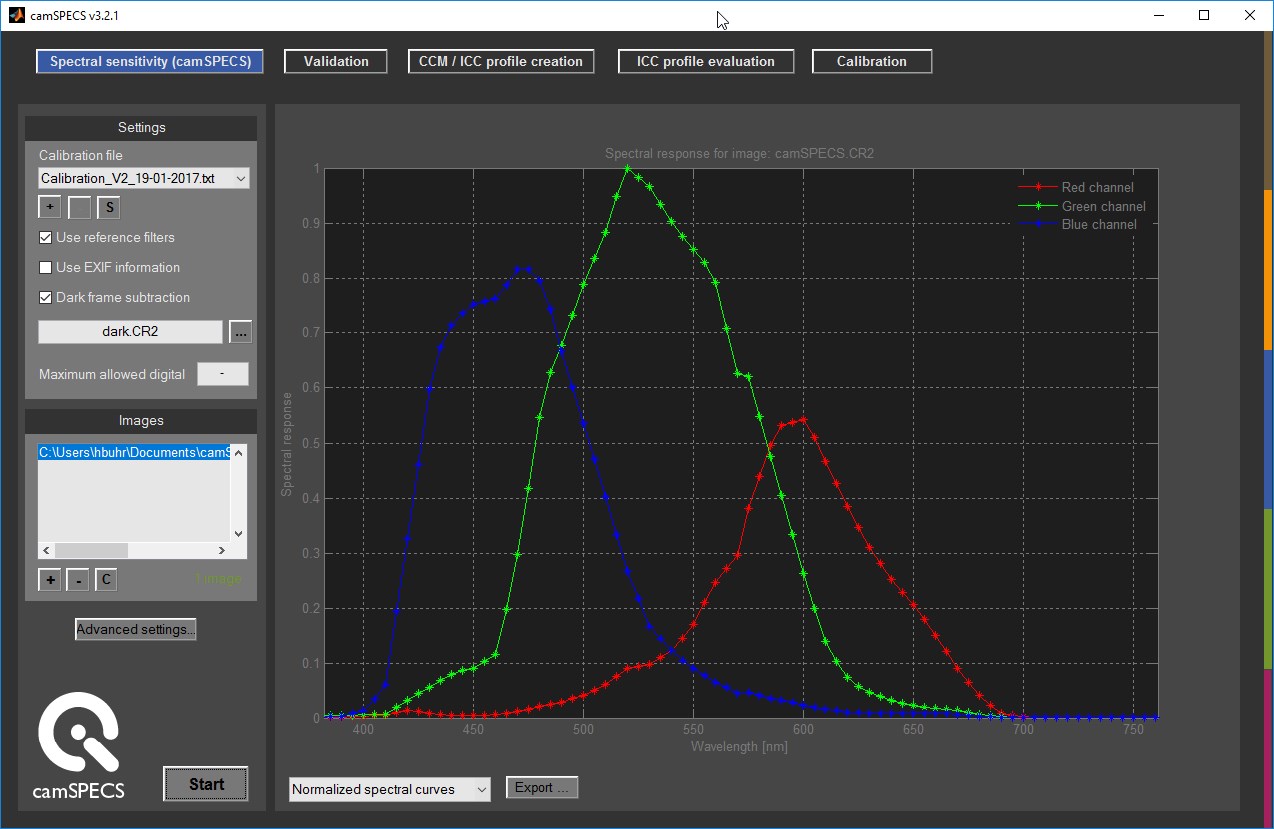

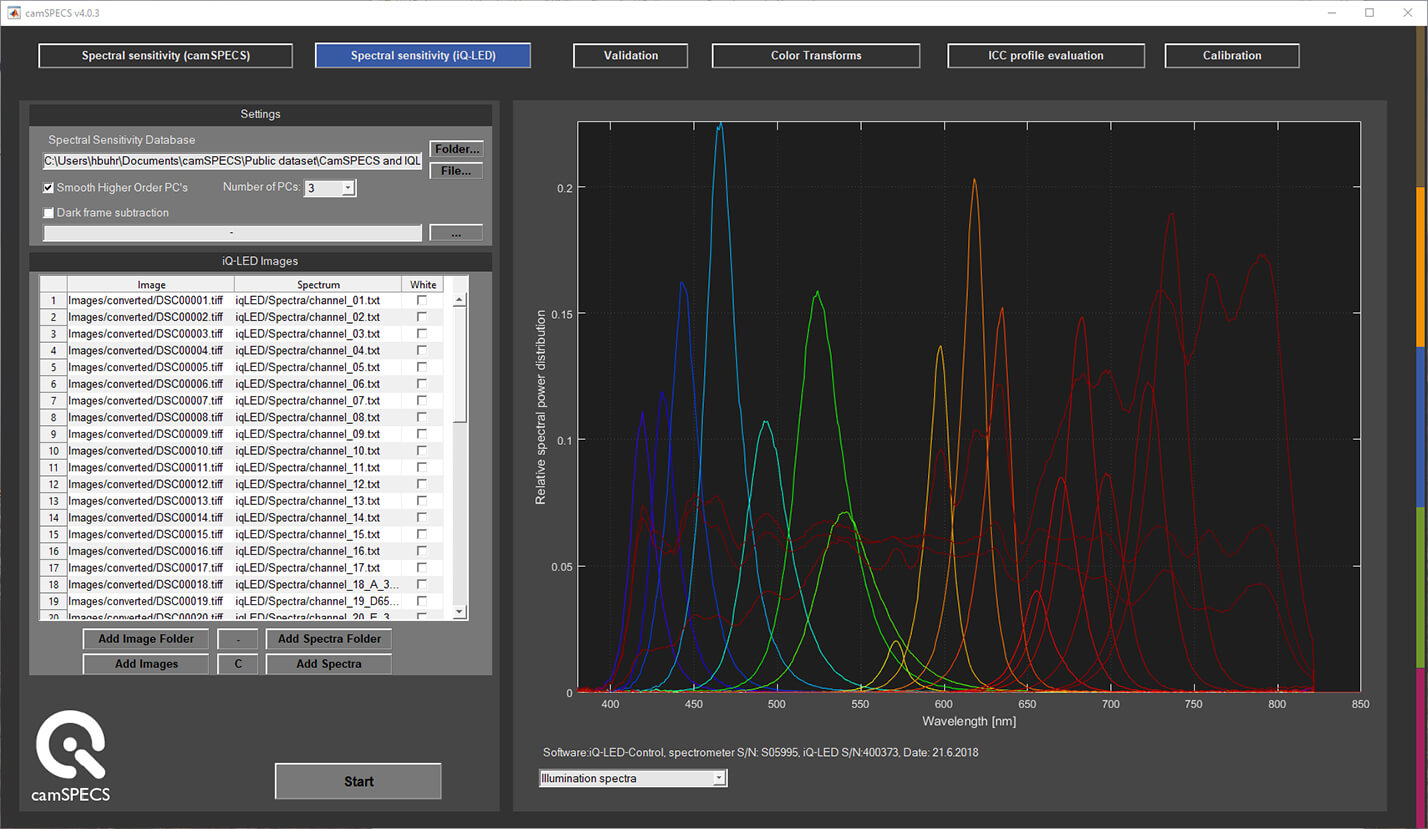

The evaluation software makes measuring fast and convenient. It calculates the spectral sensitivity with the images and the calibration data of the filters as a direct measurement, (similar to a monochromator). The software reads image files such as Tiff or common raw files* and can perform a dark frame subtraction if needed. Non-Bayer pattern sensors (for example sensors with RGB-IR or RGBC pattern) can also be evaluated. In this case, all four channels are measured independently.

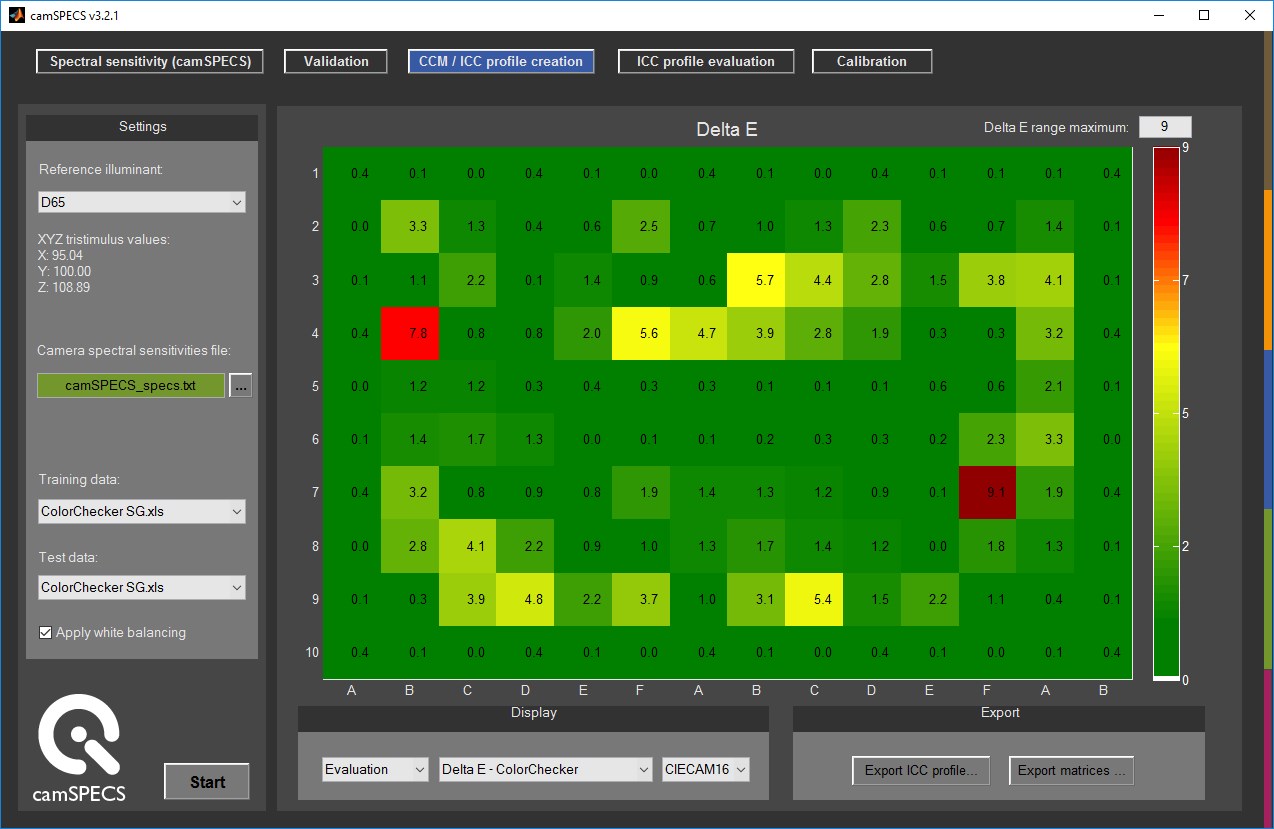

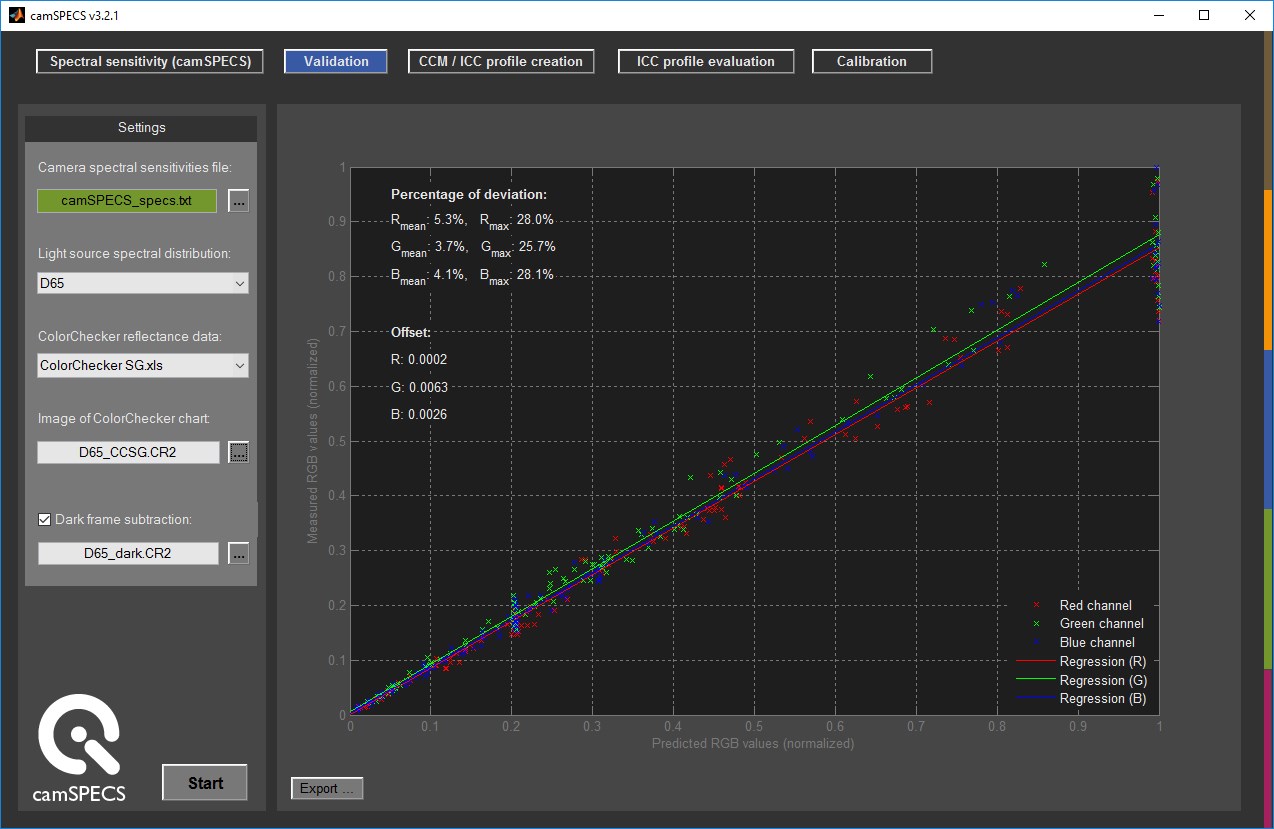

The main application for the spectral sensitivities is the calculation of color correction matrices (CCM) with the CIECAM16 model and the export of ICC and Adobe ACR profiles with 2D- and 3D-MLUT rendering. An additional feature incorporates the assessment of the measurement setup by comparing real camera data with predicted RGB values.

For the calculation of individual CCMs, the spectral radiance of natural objects from the in-situ database may be applied.

Software

- Spectral sensitivity measurement

- Generation of color transforms including 3x3 matrices and others (RGB to XYZ) with different algorithms supporting popular profile types

- Creation of ICC profiles

- Support for 2D- and 3D-MLUT color transforms

- CIECAM16 implementation for building color transforms

- A test procedure for evaluating color transforms with different training data

- RAW file* processing / dark frame subtraction

- Validation by comparing a camera and predicted RGB values

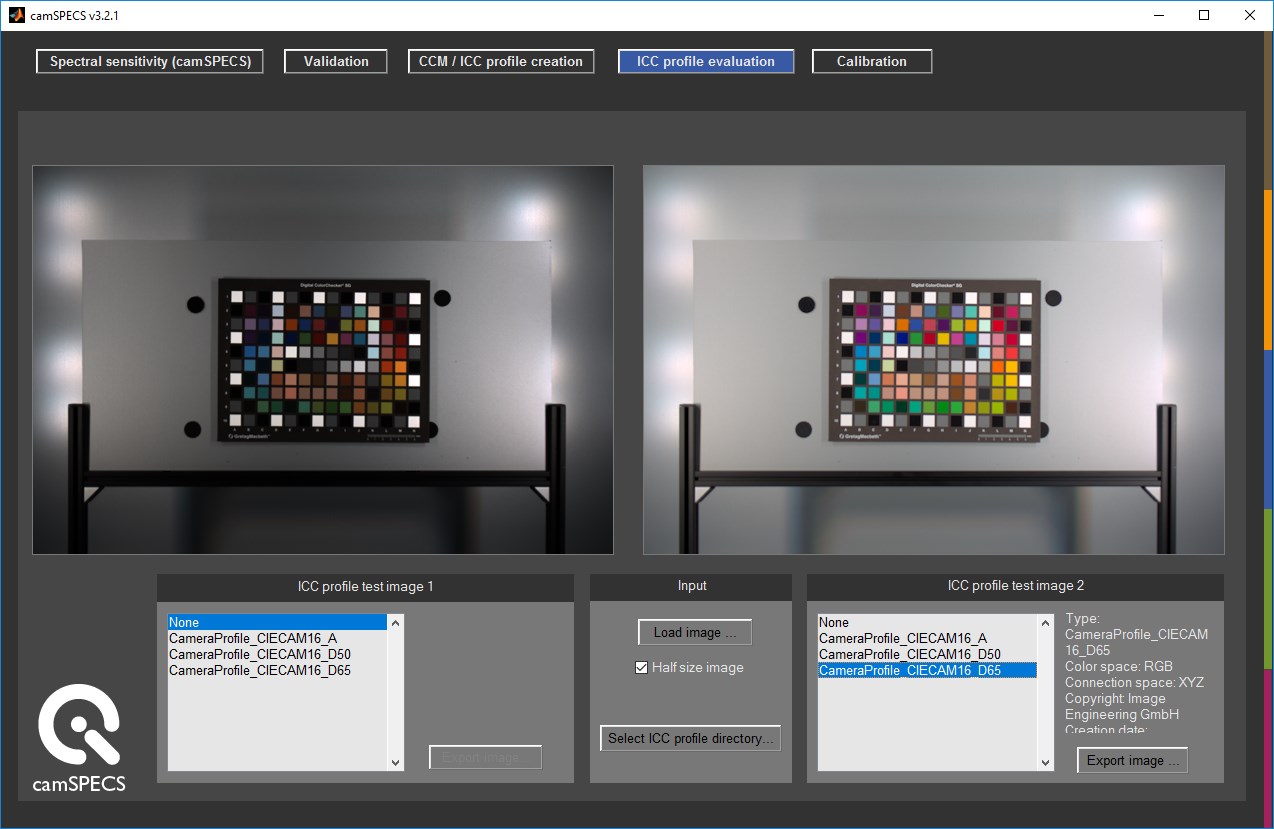

- Visual evaluation of ICC profiles with real images

- Calibration with an included calibration device

- Export of all results to XML or plain text files

Determination of CCMs (color correction matrices)

The spectral sensitivity of a camera is interesting to look at but the real benefit is to use it to calculate the best color correction matrix for the camera. The camSPECS software comes with a module that allows the calculation of such matrices. Three different algorithms are implemented, a least squares linear regression, a white-point preserving least-squares regression and the CIECAM16 model. The required input data is the spectral response of the camera, the spectral distribution of the illumination and spectral training data.

The required training data can either be the provided spectra of a ColorChecker or measured spectra from natural objects. Image Engineering can provide access to a huge database of in situ spectral radiance data. A white balancing can optionally be incorporated into the calculation of the matrices.

Color transform generation

Once the camera spectral sensitivities have been determined, there is now an option to build optimal color transforms to convert from camera values to colorimetric values. By including the reference illumination and standard charts data (or newly-available specially measured in-situ training data representative of real scenes), color transforms are built which optimize color appearance differences using CIECAM16. Various methods and transform types are supported including colorimetric matrices, white point-preserving transforms, ICC profiles, with others being continuously added.

Spectral measurement with iQ-LED technique

In a high-speed production-line within camera-module production environments, each unit will receive a frequent calibration. Traditionally, this calibration has been done with a simple white balance for one lighting condition. Using our iQ-LED-based products, it is now possible to measure per-unit camera-module spectral sensitivities, update per-module white balances and color transforms for every lighting condition of interest. This calibration is done in a few seconds and results in improved consistency, quality, cost, and yield. Our iQ-LED-based hardware, application, and API software products are available in a variety of configurations. With the advantage of self-calibration and unit-to-unit consistency, production-line camera-module calibration across multiple manufacturing sites now becomes consistent, reliable, and practical.

*In this context, we use the term “RAW file” for files that are created by a digital camera in “RAW Mode” and are readable by the dcraw software. This does not include RAW files that do not follow any readable image file format. You will have to convert these files to e.g., 16-bit linear tiff first.

| Light source | Halogen (24V / 250 W) Osram 64657 HLX |

| The durability of the light source | 300 h |

| Color temperature | 3550 K |

| Wavelength range | 380 - 760 nm (10 nm steps) |

| Bandwidth | 10 nm |

| Diameter interference filters | 10 mm (XL: 22mm) |

| Diameter ND filters | 6 mm (XL: 10 mm) |

| Stabilized power supply | Automatically adjustable 100 -240 V, 50-60 Hz |

| Power input | approx. 300 W |

| Dimensions [W x H x D] | 295 x 255 x 520 mm |

| Weight | 7 kg |

camSPECS Software V4.3.0

camSPECS software changelog (txt)

camSPECS software (Windows 64bit installer)