Introduction

One of the more significant problems facing camera system developers is ensuring that their systems function reliably in changing weather environments. This issue is particularly relevant in the automotive and security camera industries that depend on various camera systems to keep consumers and the general public safer.

An automotive camera system must be able to perform in any weather condition. Suppose a human relies on a camera system when driving, whether for something simple, such as backing out of a parking space, or more advanced, such as making safe adjustments while driving.

Regardless of the use case, these systems must function correctly in every condition, from bright sunlight to low visibility situations such as heavy fog. If automotive manufacturers ever hope to achieve level five autonomous driving (i.e., zero human interaction with the car).

The same is valid for security and surveillance video camera systems. If the system cannot accurately detect and record objects in, for example, low-light scenes, the subjects in the scene may be exposed to dangerous situations.

Relevant KPIs

Testing camera performance in extreme weather conditions is generally no different from traditional camera testing. The camera system must be able to pass defined thresholds for various image quality factors such as resolution, texture loss, noise, distortion, color accuracy, etc. However, certain industries that rely on cameras for consumer safety require specialized factors or more rigorous testing.

Contrast transfer accuracy (CTA)

Contrast Transfer Accuracy (formally known as contrast detection probability) refers to the ability of a camera system to correctly identify an object's contrast in its field of view. The IEEE-P2020 working group developed CTA as a key performance indicator (KPI) for ADAS and other automotive camera systems. The automotive industry, in particular, must ensure that its cameras can identify different contrasts to make the correct and safe adjustment. All the more critical is to perform at the same high level in changing temperatures and sometimes blinding weather environments.

Image stabilization

Image stabilization refers to how stable the optical system of a camera is during image capture or video recording. If a camera is not steady, the image may appear blurry. Typically, image stabilization issues mainly occur from handheld cameras. However, with increasing reliance on camera systems in more areas of life, stabilization issues must now be accounted for with other systems, especially in rapidly changing environments. For example, how does an automotive camera react to bumpy roads, or how do high winds affect an outdoor security camera system? Testing the stabilization of these systems is imperative to achieve a high level of performance.

Low light

Low-light situations are often the most challenging environment for camera systems. Low light describes the lowest light threshold where a camera can still produce adequate image quality. ISO 19093 describes various low-light thresholds that camera systems should be able to attain to maintain safety and performance. This KPI is significant to automotive or security cameras often performing in low-light scenarios. Safety and performance will be compromised if an automotive camera, for example, cannot detect objects correctly in changing light or at different temperatures.

Flickering light

Light flicker is a periodic change to the brightness or intensity of a light source. Light flicker can occur from many sources, including flashing lights from emergency vehicles or road signs. It can also occur during storms or other naturally occurring instances. Weather events and rapid changes in temperatures can create changes in light sources, and thus a camera system must be able to adapt, particularly where safety is concerned.

Temperature-controlled testing

In the past, traditional camera systems were not thoroughly tested for their performance in changing temperature/weather environments. This lack of testing was partly because many cameras were not used in dynamic environments and were instead used in temperature-controlled environments (e.g., in factories, buildings, etc.). Another part was that testing camera systems in a test lab was complex and outdoor testing was unreliable.

However, with the rise of automotive cameras and other systems used in recreational activities (e.g., GoPro), these cameras began requiring proper test equipment, methods, and international guidelines to define and support safety and performance specifications. Today many standard committees are working towards establishing international standards for these camera systems.

International standards

Many international standards relating to testing in changing temperature/weather environments are under development. However, developing standards for industries relying on cameras for consumer safety has become crucial.

Automotive standards

One of the most challenging issues for automotive cameras is to be perfect. To achieve fully autonomous driving, we must ensure the camera systems don't make mistakes regardless of the environment. Establishing the right KPIs and utilizing advanced testing equipment can help ensure these cameras perform safely. The most prominent committee working on establishing an image quality standard for image quality is IEEE-P2020.

As previously stated, IEEE-P2020 is the group behind developing new and essential automotive KPIs such as contrast transfer accuracy (CTA) and modulated light mitigation probability (MMP), also known as flicker. They also establish test methods and image quality thresholds for manufacturers to use when testing their systems. During development, these KPIs must also be tested for performance in changing temperature environments. Advanced test equipment such as the iQ-Climate Chamber allows this in a test lab setting.

Security and surveillance standards

We have become very reliant on security cameras in our everyday lives. Whether it be surveillance cameras, drones, etc., these systems must be able to perform at the highest level to ensure safety for the consumer. As with automotive cameras, establishing the right KPIs, test methods, and equipment is crucial to test security cameras to ensure adequate performance and safety. The most established standard for security camera testing is IEC 62676-5.

IEC 62676-5 defines KPI thresholds that security cameras must attain to be considered safe for consumer use. These KPIs include contrast separation, texture loss, noise, color accuracy, etc. The standard also establishes test methods, often requiring advanced equipment such as the TE269C test chart.

In addition to IEC 62676-5, a new amendment to the standard is currently under development. It will be known as IEC 67676-5-1 and establish new KPI thresholds for security cameras in different temperature/weather environments. These KPIs will require advanced test equipment, such as the iQ-Climate Chamber, for testing in a controlled environment.

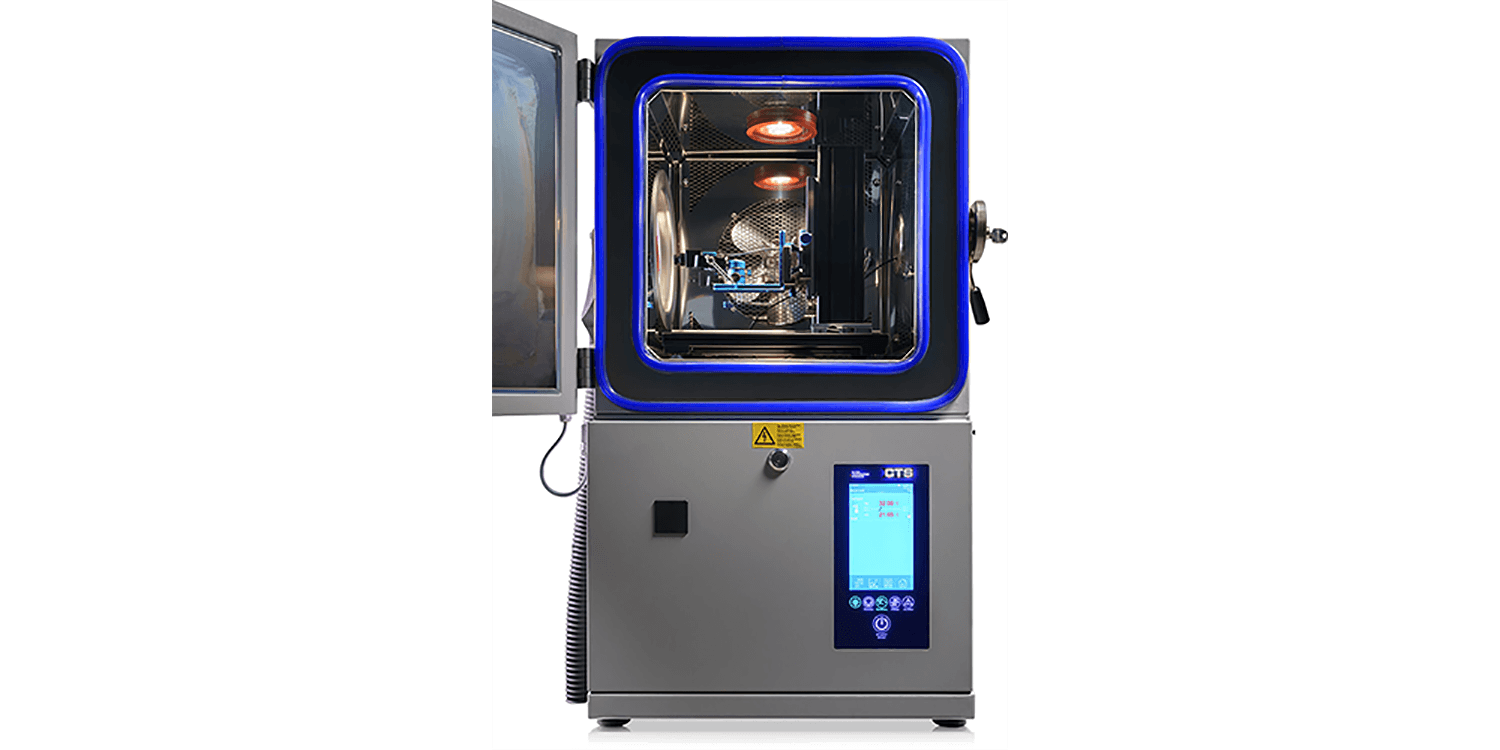

iQ-Climate Chamber

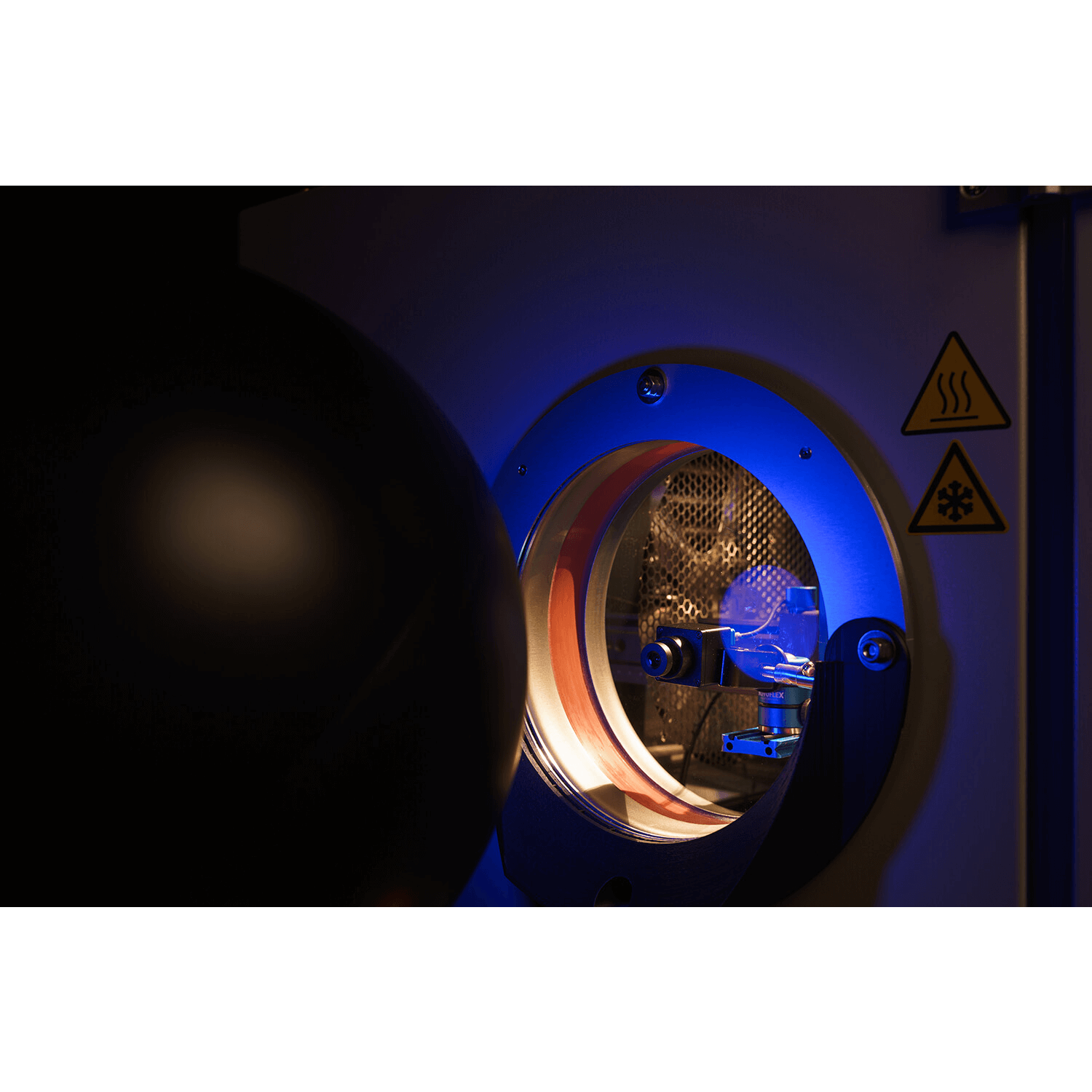

Over the last few years, it has become apparent that many camera systems need to be tested for their performance in changing temperature environments. How will an automotive sensor perform at temperatures below freezing? Or will their performance be affected in temperatures above 100°C? And how can we accurately test a camera for these temperature fluctuations in a controlled test lab? Our engineers set out to create a solution to this challenge and developed the iQ-Climate Chamber solution.

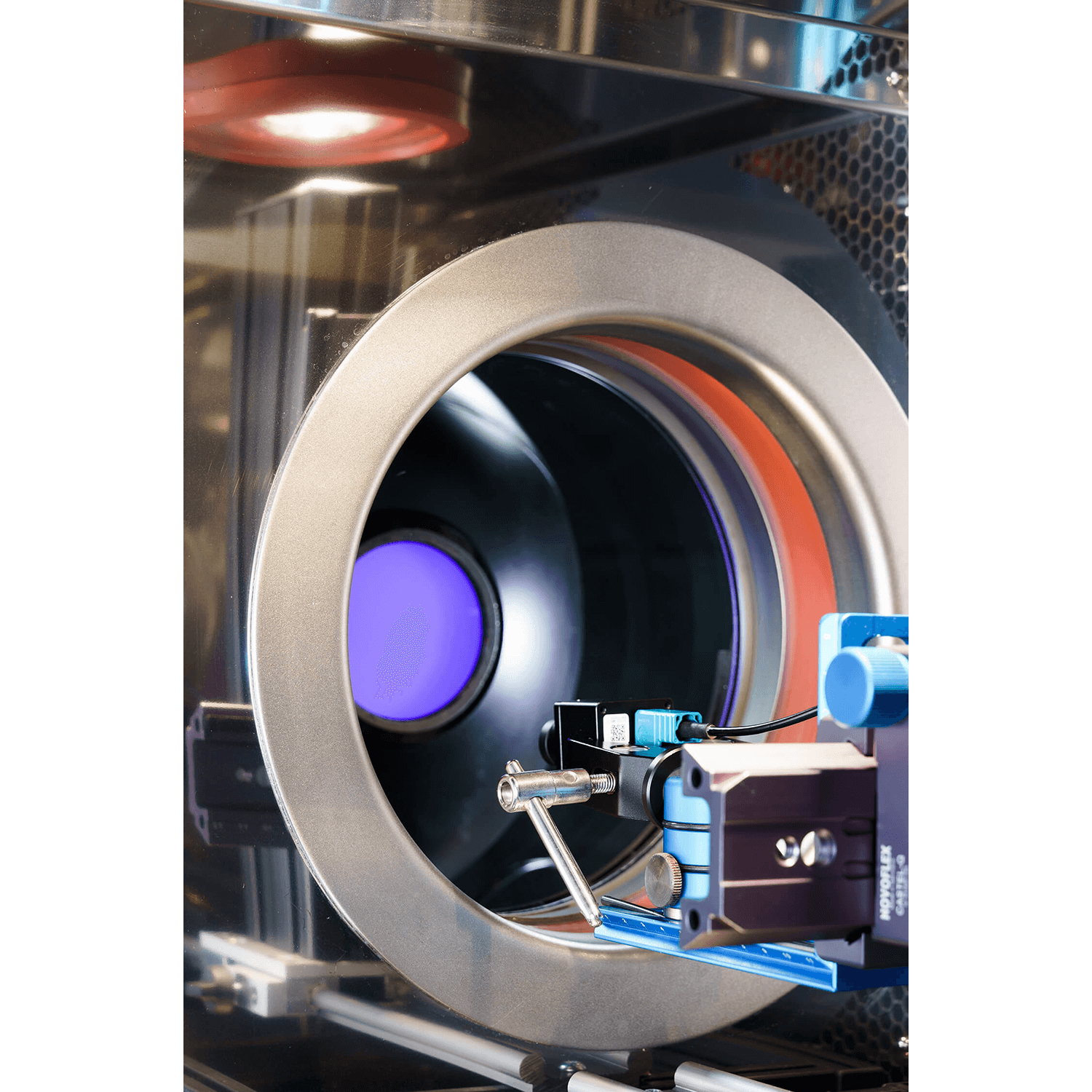

The iQ-Climate Chamber solution allows the user to set a temperature between -40 to 120 °C in a test lab environment. Place the camera or sensor into the chamber with the lens pointing out the porthole window. Once safely shut, users can input the temperature they wish to test in. A remote trigger allows the capture of test images through the window. This solution has quickly become a vital tool for all those designing cameras for outdoor environments with changing temperatures.

Testing solutions

While the iQ-Climate Chamber is the central solution when analyzing a camera's response to changing temperatures, it still requires other tools, such as test targets, to maximize efficiency. During the set-up of the chamber, the device under test (DUT) will be placed in the iQ-Climate Chamber with the lens pointing out of the porthole window and toward test targets or light sources. Images captured of the test targets and light sources will help determine image quality performance at different temperature intervals.

Ideal test charts depend on the DUTs requirements, but when we use the iQ-Climate Chamber solution in our iQ-Lab, we typically use the TE42 multipurpose test chart. This chart allows us to test numerous image quality factors such as resolution, texture loss, color accuracy, dynamic range, noise, and distortion in one test image. We recommend illuminating the test chart using the iQ-Flatlights, powered by iQ-LED technology. This technology lets you generate custom spectra to analyze the DUT's reaction to changing and low light. Other iQ-LED devices, such as CAL1, can be set up directly in front of the porthole window for camera calibration and characterization.

Combined with the iQ-Climate Chamber, these solutions provide a powerful tool for evaluating a camera's performance in fluctuating temperature scenarios from the comfort of a test lab.

Contact us

Contact us at for more information on the iQ-Climate Chamber and other temperature testing solutions.