A VCX lab for webcam testig

A customer success story

The VCX standard has become one of the leading sources for evaluating the performance and quality of mobile phone camera systems. What makes VCX unique is the development of an objective “score” given to each camera that undergoes VCX testing as outlined in the standard. The consumer can use the VCX score to find the perfect camera.

In early 2021, the VCX-Forum was approached by a handful of companies focusing on developing webcam systems. The standard is still under development, but many companies worldwide have begun equipping their test labs for VCX webcam testing.

One of the first companies to build a dedicated VCX webcam test lab was Dell TDC (Taiwan). Dell is heavily involved in developing the standard, and now, with one of the first VCX webcam labs, they have established themselves as a leader in webcam performance testing.

Follow the link below to read more of Dell’s story.

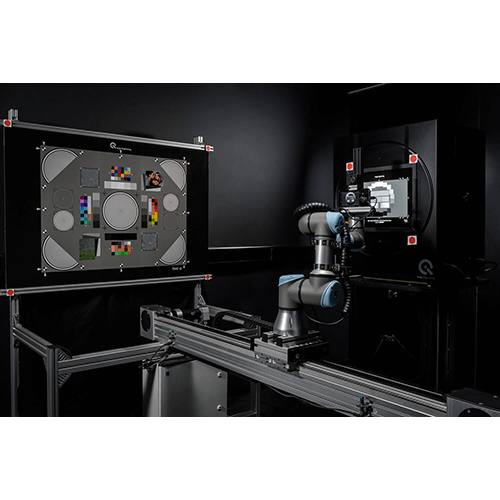

Building an image quality test lab

We've helped companies worldwide build image quality test labs

Building an image quality test lab can be challenging for companies of any size, as many factors must be considered to ensure you are getting correct and reliable results. We have assisted companies that are building a new lab from scratch or those just looking to upgrade a section of their current lab.

For those looking to get an idea of what it takes to build an adequate image quality test lab, we have put together a list that includes requirements and recommendations for setting up a fully functioning image quality test lab.

Already have a lab, but not sure if it’s fully optimized? We can help! Contact us for expert advice on improving the state of your test lab and ensuring your testing is as accurate as possible.

Camera calibration on a production line

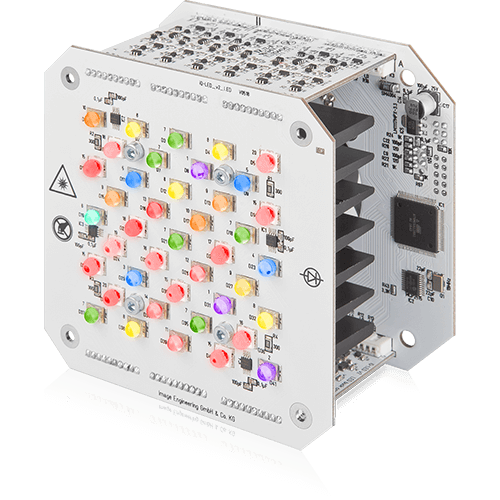

iQ-LED technology for camera calibration on a production line

One of the most frequent questions we receive is, “how can we optimize our camera module calibration on a production line?” Our answer is iQ-LED technology. iQ-LED technology can generate custom spectra in a controlled lab environment. This ability is particularly relevant for production lines as you only need to implement one light source into the workflow that can produce any type of spectrum e.g., daylight, tungsten, etc.

A full camera calibration can then be completed in a matter of seconds due to the short response time of the LEDs, as long as the image processing and transfer of the camera is fast enough. On a production line, multiple camera modules can be calibrated at one time, significantly improving the effectiveness of your workflow.

CAL2

An integrating sphere for production line camera calibration

The most efficient option for integrating iQ-LED technology into a production line for camera calibration is to use an integrating sphere. The CAL2 is an ultra-compact integrating sphere, and its patented edge box design makes it particularly suited for calibrating cameras on a production line. A non-reflective diffuser filter with improved Lambertian characteristics on the box opening ensures illumination uniformity.

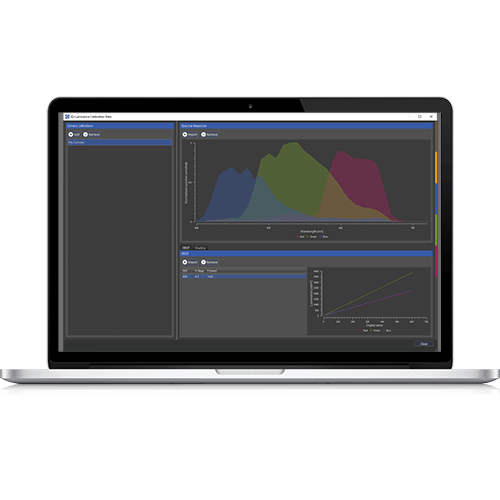

iQ-Luminance software update

Version 3.1.0 is now available

The latest version of the iQ-Luminance software introduces many new upgrades, including a general revision of the user interface and result table. Most notably, we have extended the ROI handling flexibility. You can now select and resize multiple ROIs in the image plot. In addition, you can edit, delete, rename, and import and export ROIs to/from the UI. We also have more options when exporting results as a PDF.

For those who have purchased version 2.2.5 or older, you will need a license key to access the latest version. Please contact our sales team to receive your key.